The new era of manufacturing

In the Tampere region, there exists a firm belief in the new methods offered by 3D-printing, and the region has been determined in being in the forefront in utilizing the new technology and its applications. The projects 3D Boost and 3D Invest make up a formidable pair, which help create top-notch expertise to the region, and through which new scientific areas can be explored.

The projects are a cooperation between the Tampere University of Technology, the Tampere University of Applied Sciences, and SASKY Municipal Education and Training Consortium. This ensures that that there are experts available in a multitude of different fields. The objectives of the projects were consciously divided into two parts, says Hannu Kivilinna who heads the industrial technology faculty at the Tampere University of Applied Sciences.

“With 3D Invest we procured the necessary equipment, and with Boost we engaged in research activities as well as disseminating information to the regional companies about 3D-printing. When we procured the equipment, we paid close attention to the process so that there would not be any overlap regarding the equipment. This ensures that we have a broad portfolio at our disposal”, Kivilinna explains.

With the synergy of the projects, the Tampere region is creating an internationally known centre for knowledge and applications, where the whole production chain from research and design all the way through to the manufacturing of the end-product is handled by national companies.

“There is no doubt that if we do not have our own knowledge pool in future, we will be forced to buy the products from abroad”, Kivilinna emphasises.

3D-printing and the technologies surrounding it are a rapidly growing market which might have manifested themselves to the private consumer too. The printers aimed for private use will set you back around two hundred euros, but the equipment used in research and industrial manufacturing are in a class of their own, Kivilinna explains.

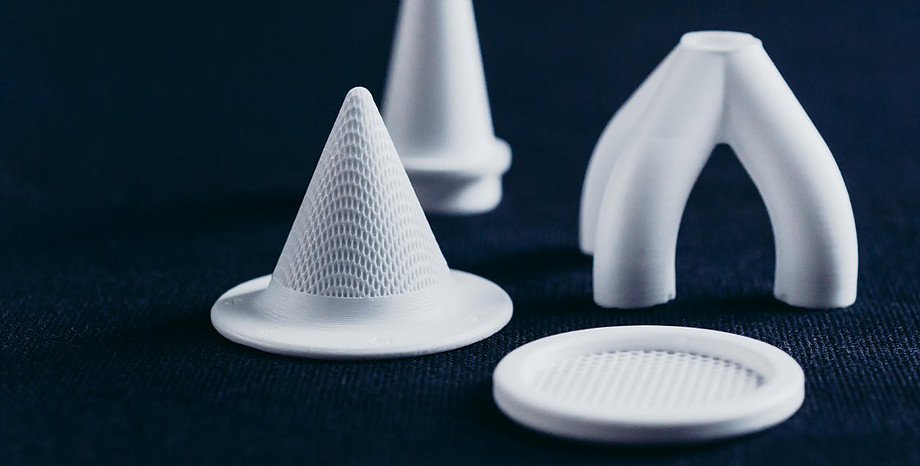

In addition to the cost, the materials used by the printers vary wildly. For example, with the equipment procured through 3D Invest, the users can “print out” metals and ceramics in addition to the more familiar plastic, says Kivilinna. Each of the three partners in the projects have their own kinds of equipment that use varied materials, and which support each of the triumvirate’s area of specialty. This guarantees that each of the three participants’ roles and interests are taken into account.

TUT has at its disposal metal and ceramic printers, and its activities are aimed first and foremost to the areas of scientific research. Tampere University of Applied Sciences, meanwhile, focuses on the education of future designers and production managers, so the equipment needed to be able to match highly demanding tasks. SASKY takes aim at the need to educate professionals who can operate a high number of various equipment in the processes of production.

“Among professionals, the term ‘printing’ is eschewed. Rather, we use the term ‘additive manufacturing’ (AM) whose main difference to traditional manufacturing is that, in the latter the process removes material, for example, from a sheet of metal, whereas in the former we are adding material until the desired product is finished”, Kivilinna clarifies.

Even though there is immense potential in the AM method, it is not yet at a stage where it could offer a bespoke solution to the problems faced by the manufacturing industries, says Kivilinna. One crucial factor in the future of the AM method is how well the various companies and corporations know the workings, limitations, and opportunities of the method.

“We have partnered with companies to whom we have disseminated information and skill concerning the AM method, in the framework of the projects. In addition, we can manufacture products to the specifications from the companies which have been designed either by the companies in isolation or in cooperation with us”, Kivilinna explains.

With the AM method, the user can manufacture products that might not immediately fit into the mental category when we think about “printing”. Essentially, any product, be it jewellery or prosthetics, can be manufactured using the method. All it takes is clever design and the suitable materials.

According to Kivilinna, there is much work to be done especially regarding the designing of the products, as the AM method requires a different approach to design that the traditional methods. Part of the designers, he says, can be a bit too attached to the old ways of doing things but this is something that is being tackled by the 3D Boost project. Finland is in a favourable position in the global scale in utilizing the AM method, even if the country cannot compete with powerhouses like Germany, for instance.

The projects have also gained international renown as they have been selected to be the finalists in the European Regio Star Awards 2017 whose winner will be announced in the October of 2017. Kivilinna states that the projects have come into being at the right time and place, as the Tampere region is avid in furthering its understanding and knowledge regarding the technologies. The best-case scenario, for Kivilinna, would be if Finland could attract existing companies and to create new ones that would export their products abroad.

“There has been a lot of hype surrounding the AM method but we must tread carefully around it. Not everything will be manufactured using the method, as for example manufacturing an axle is, so far, easier and cheaper with the traditional methods”, Kivilinna stresses. On the other hand, by using the AM method, small and even unique series of products can be manufactured. These unique series include a knife-handle designed and manufactured by Antti Korpi, which won him the Finland100 3D-Printing competition in 2017.

It is the production and manufacture of small and unique series of products that hold the greatest potential for the AM method, according to Kivilinna. This opens up possibilities and opportunities to the areas outside traditional industries. For example, the health care sector can greatly benefit from bespoke instruments aimed at surgeons and personal prosthetics for patients.