The new winds of digital manufacturing

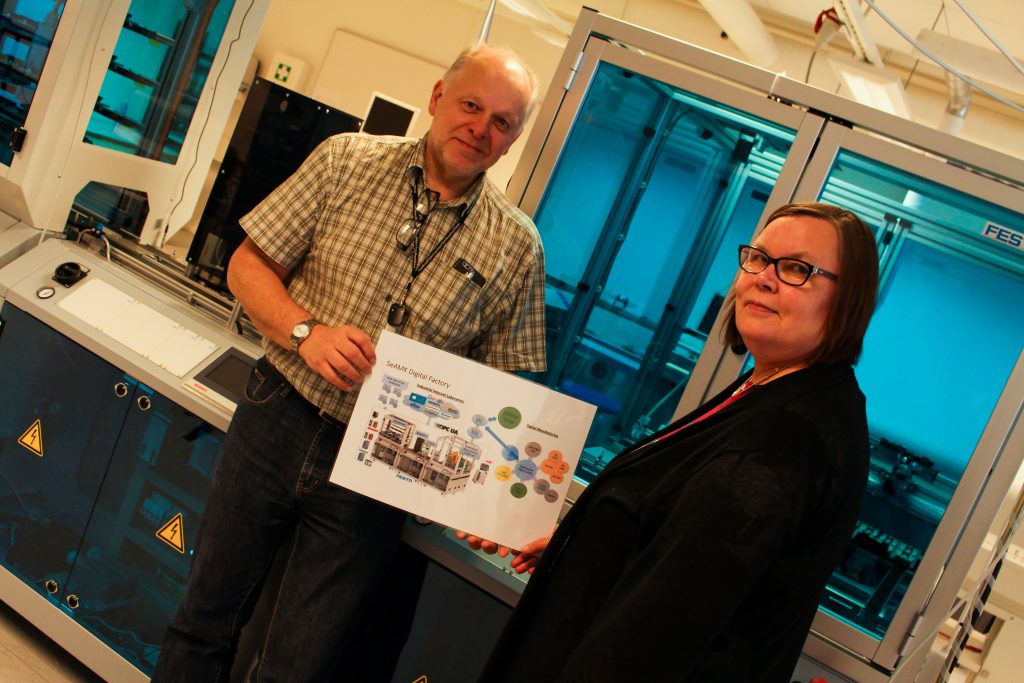

It comes as no surprise that digitalization and automation have conquered much of the manufacturing industries. The Internet of Things (IoT) and the fourth industrial revolution are concepts that have spread far and wide, and which have been grasped by Seinäjoki University of Applied Sciences. As a result of extended development, a new study environment and a talent cluster has been created, and its name is SeAMK Digital Factory.

“We organized a seminar for the representatives from the European parliament recently, and the case study in it was SeAMK Digital Factory and its story”, says Kati Katajisto, who works as a Research and Development Manager in the SeAMK school of technology. The story is indeed worth telling, as it serves as a good example in how the belief in your own work and the desire to act upon it can bring about great success.

The story begins in 2013 when SeAMK started the SeAMK Digital Factory project with funding from the European Regional Development Fund (ERDF). During the project, a new kind of a learning environment was built and developed. The environment allows for the management of entire production processes, and it is used to teach the students of mechanical engineering, automation engineering, and information technology. At the same time, a network of the regional SMEs interested in digital manufacturing was created, with the aim of enhancing the know-how of the participants.

Following the original SeAMK Digital Factory project there were the Agile Industry, KoKiKe, Digivaattori, HardSoft, Tibori, and Kyberi projects. Each of the projects had their own, focused goals and the means to achieve them. However, each of them were linked to the applications of either digital manufacturing or the industrial Internet.

SeAMK Digital Factory has received a lot of positive feedback and has been the winner of a number of awards, despite its rather short lifetime. This has enabled its brand to gain momentum and strength. Just a few of the awards won by SeAMK Digital Factory include the Eläköön automaatio! innovation competition in 2015 and the first place in 2016 of the national universities of applied sciences’ RDI-competition TKI-Kärjet. Perhaps the most noticeable win was from the Tuottava Idea competition in 2016 through which SeAMK Digital Factory got its logo on display at the famed New York Times Square.

As for the projects mentioned above, Tibori and Kyberi were closely linked to the laboratory of industrial Internet, as they helped build the laboratory. Additionally, they were in a critical role in defining the modern shape and figure of the SeAMK Digital Factory. The Agile Industry project is aimed at the SMEs of the region in realizing the opportunities offered by digitalization and the industrial Internet, whereas the Digivaattori project is focused on the training and education of the personnel of the regional SMEs. As per its name, HardSoft brought together the physical hardware and their software in a novel learning environment, wherein machinery and programs could be tested virtually before the initiation of a production line.

As the leader of the projects, Seinäjoki University of Applied Sciences has been able to increase the know-how of the regional actors and their readiness to use the various tools offered by digitalization. At the same time, SeAMK has succeeded in bringing together students and research to work on the projects, according to Hannu Reinilä, the head of the degree programme for the school of technology.

“Our students are not able to receive the important comprehensive perspective concerning the functions of a company, which range from design to production, simply by attending isolated courses. By bringing them to the learning environment at the very beginning, during the first few weeks, they receive the vital understanding and motivation. When they graduate, they know the systems and programs used by the companies intimately. In this way, they are already semi-professionals which benefits not only them but also the companies,” Reinilä continues.

Both Katajisto and Reinilä place their trust in the multi-disciplinary culture, because it gains more and more importance in the working life. They want the students to carry their accumulated technological wisdom and their competence to the companies in which they will work after graduating. Opportunities to be acquainted with the SeAMK Digital Factory and its workings have also been presented to various companies. This co-operation has enabled the creation of co-projects between the students and the companies.

“The digital learning environment has given a start towards the dismantling of the borders between the traditionally segregated fields of study. This dismantling is important because in a successful company nowadays, the different occupational groups understand what the others are doing, and their inherent importance. Mechanical engineers, IT-engineers, and business people are sharing the drawing board more and more often, these days”, Reinilä emphasizes.

On the noble quest for knowledge

Projects carried out previously showed that the SMEs in the region did not have sufficient knowledge about the tools, opportunities, and advantages brought on by digitalization, according to Katajisto. The Agile Industry as a project is meant first and foremost for the regional actors in order to activate them. Seminars and workshops are organized through the project, which increase the knowledge and skills for the use of the new tools.

“In the beginning only about 20 per cent of the regional actors knew what impact on the manufacturing industries digitalization had, or what it meant or offered to them. Now, the situation has flipped upside down, but unfortunately only a handful of the regional actors have actually done something regarding this,” Reinilä explains.

There is indeed a high demand for education, as the European commission estimates that SMEs can expect an increase of around a hundred or two hundred per cent in growth brought on by digital technologies and techniques. Despite of this, only 1,7 per cent of the SMEs operating within the EU are taking advantage of the benefits of digitalization to the fullest degree.

One might imagine that bringing such an abstract and difficult-to-grasp concepts as digitalization and the IoT into the world of the physical would prove to be a difficult task. The issue was also acknowledged in the Seinäjoki University of Applied Sciences, and the laboratory of the Industrial Internet is aimed at bringing the information that exists as bytes into the physical environment wherein it is made concrete to the companies, Katajisto explains.

The dissemination of information from the SeAMK Digital Factory goes beyond the regional SMEs as, according to Reinilä, other Universities and Universities of applied sciences have also shown their interest in their operations. This interest has led the others to come up with their own ideas and plans regarding the area of digital manufacturing. This does not bother Reinilä, on the contrary.

“Many have asked me about other copying us and don’t we mind that the similar operations have sprung up in other locations. My answer to that has been that no, it does not, as our skills are something that cannot be taken away. We have accumulated a lot of knowledge and skills. Each of the different actors are creating their own know-how and supply based on their own starting point,” Reinilä says.

One of the regional corporations that have engaged in cooperation with the SeAMK Digital Factor and other projects is Pesmel Inc. The company’s chief product manager Marko Nousiainen praises the high level of engineering knowledge available to the company from right next door.

“Our cooperation with the Seinäjoki University of Applied Sciences has been in effect for a long time, and we recruit numerous students for the company through the students’ thesis work. These young people are well situated to understand the future and new ways of doing things”, he explains.

The company has been in the forefront in utilizing the tools and opportunities offered by digitalization and the fourth industrial revolution. According to Nousiainen, these will gain more and more relevance when the new generation of workers graduate from the universities. They will be bringing their own sets of skills and knowledge on the new methods of working in new environments.

Innovative networks for Europe

Through the previous projects, SeAMK Digital Factory and the networks created through the various activities are on a fast track in gaining a foothold on the international playing fields. The project IoT-Compass Hub is linked with the EU-wide initiative called Factories of the Future. The initiative aims to spread the knowledge and skills gained from research activities to the SMEs operating within the EU. IoT-Compass Hub is part of the Digital Innovation Hub network, which operates in various EU countries. The goal of the network is to broaden the horizons and skills related to advanced methods of manufacturing. For the time being, the Seinäjoki hub is the only one of its kind in Finland, so it has excellent opportunities for success.

The project includes the Tampere University of Technology through which the project gains cutting-edge research data. The data finds its applications through, for example, the SeAMK Digital Factory and its undertakings. Since 2003, TuT has organized retraining programs in Seinäjoki University of Applied Sciences for engineers who have graduated from SeAMK.

In addition to the cooperation with institutes of higher learning, SeAMK Digital Factory has an extensive network of partners in the fields of business. Partners who benefit from SeAMK Digital Factory include Siemens and IDEAL PLM. Many might recognize Siemens as a manufacturer of electronic goods and IDEAL PLM brings front-line knowledge on the development and use of different software, Reinilä explains.

Reinilä and Katajisto are visibly excited about the opportunities offered by the Hub network, and rightly so, as the network opens up wide vistas filled with brilliant knowledge networks. Furthermore, the Seinäjoki hub is mentored by ingenious professionals from Milan, and has the international support of the aforementioned companies and Beckhoff Automation Inc.

Cooperation is vital for small countries such as Finland because despite of the readiness in certain areas to utilize the tools offered by digitalization, it cannot compete with the global economic juggernauts. According to Reinilä, the visions regarding the effects caused by automation and digitalization are based on facts, though they are perhaps slightly exaggerated.

“Our objective is to create a top-notch network of partners through the Hub in a few years. Southern Ostrobothnia might have a reputation for going at it alone, traditionally speaking. This has got to change in the future because the work settings of tomorrow are so broad that no one company or corporation can tackle them alone,” Reinilä predicts.

Nousiainen shares Reinilä’s assessment, and according to him the Finnish companies have an edge when it comes to independent and creative thinking and working. This is aided by the fluidity of the industries. However, Nousiainen would like to see more investments towards the teaching of young students by having them, for example, learn how to code in the elementary school.