New applications and savings through foam

One of the most potent defining characteristics of Finland and the Finnish people is the forest whose trees have been shaping the economy and industry of the nation for centuries. Modern industry and researchers have not merely been basking in the glory of bygone days and past achievements, but are always looking for innovative ways to utilize the raw material provided by the trees. One of these ways is a process called foam forming whose technological capitol is in Jyväskylä where researchers are coming up with new ways on how to use the decades old technique.

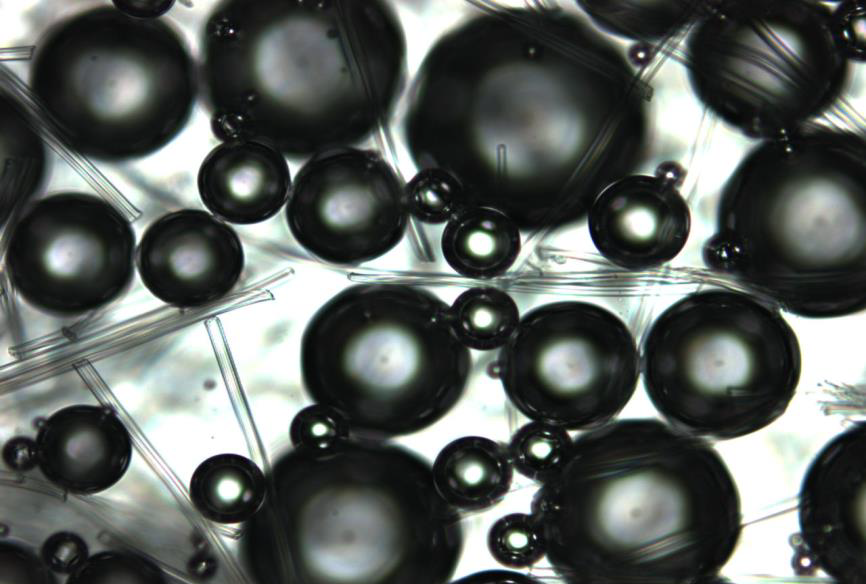

In the process of foam forming, the traditional equation of water and fibre used by paper and cardboard industries gains an additional component: air. The result is a foam consisting of water, air, and fibre, which includes the advantages of producing a smoother product, saving resources thanks to the lower density of the product, and the possibility to use a wide array of different materials, says Erkki Hellén, who works as a key account manager for the Technical Research Centre of Finland (VTT).

“By using the process, we can achieve a greater resource efficiency which is a major factor, especially for the forest industry. The technique originates from the 1970’s when it was used to manufacture specialty products, for example nonwoven fabrics, but not in the production of paper of cardboard products. After a time, foam forming disappeared from the public eye, though the companies kept at it in secret, even to this day. Our objective is to bring the technique available to a wider array of industrial companies”, Hellén describes.

The project titled Foam forming – towards industrial applications is, according to him, part of a continuum that began in 2008 and which has other projects running parallel to it. The main focus of the project is to familiarize the different industrial companies and corporations in the use of the technique, and to create a capable problem-solving environment which can expedite the technique’s adoption in a large industrial scale.

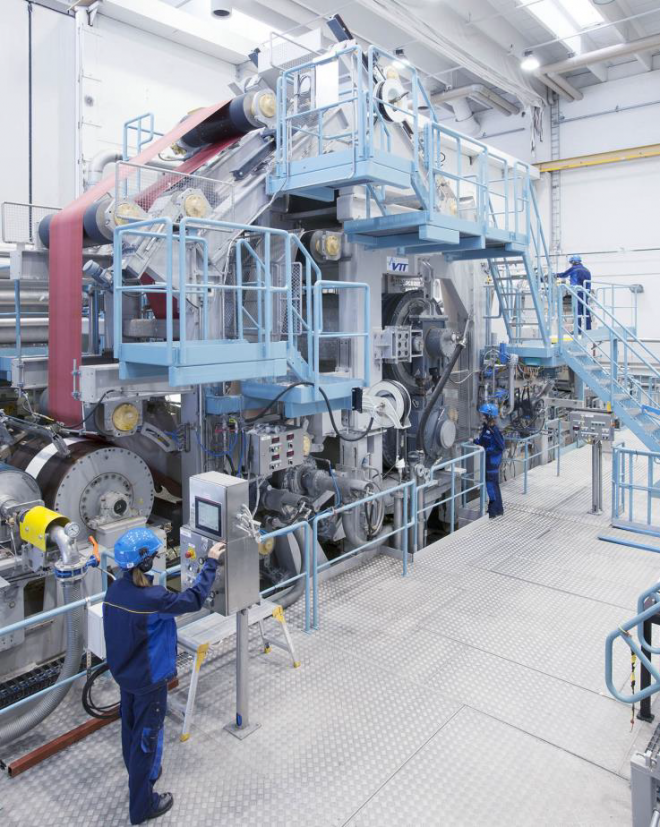

The project consists of two stages, the first of which focuses on researching the most potential applications for the technique and which identifies the potential problem areas from the perspective of the industry together with partners from the sector. The objects of research include the necessary adjustments to the processes, industrial-scale chemical processing, and the raw materials and product features used by the technique. The second stage includes the demonstration of the process solutions and the manufacture of test products by the VTT on a pilot-scale.

The markets are ripe for the introduction of the foam forming technique into the realms of paper and cardboard industries, as the combined market value of the cardboard, carton, and nonwoven fabrics exceeds 200 billion euros, Hellén points out. The technique has some major potential and in the future, it could be used, for example, to produce various kinds of materials for insulation. As a concrete and public example, Hellén mentions a spin-off company from the VTT, Paptic Ltd., which manufactures novel recyclable materials which are consist of 80 per cent renewable resources, the majority of which are plant materials. These recyclable materials can be used as replacements for plastic, for example in shopping bags and other packaging solutions.

The project is linked tightly to the national shift towards the use of renewable materials and the focus on the bio industries in the different sectors of manufacturing. The aim is to reduce the carbon footprint and to increase the usage of natural materials.

“The attitudes of the various actors within the industry are positive towards the technique. But it should be kept in mind that we are talking potentially massive investments in equipment and the skills required to use them, so the emergence of the technique on the markets might appear slow. Foam forming has a substantial influence on the industry and we are in the process of creating a consortium wherein the different companies and corporations can develop the technique together. This will mean the lowering of risks and the individual investments required”, Hellén explains.

According to Hellén, the role played by VTT is to provide the latest information and knowledge to the different actors so that they can start to commercialize the new findings. As to the project, VTT is acting as the leader within its framework, in addition to which it brings together the different companies, researchers, and corporations both on the national and international level.

“We participated in the world’s largest paper conference, Tappi Paper Con, in 2015 and 2017. There were almost two thousand participants, and twice we hosted a seminar about the foam forming technique. The seminar included diverse companies who shared their tales regarding the technique which were well received, and we received a lot of interested enquiries concerning the technique”, Hellén expounds.

VVT is also organizing corporate visits to Jyväskylä for the international actors within the industry, and is creating networks which can be utilized by the national companies. In addition to these, the activities by VTT include publications, webinars, and cooperation with different universities and research institutes.

There has been a conscious effort to create a high-quality environment for innovation and research in the Jyväskylä region. This environment is perfect for the development of novel methods and technology, and the region boasts an impressive host of experts in various fields. For example, there have been numerous researchers, technical staff, and data-analysts working on the project.

“It is a fine thing that the regional institutes and actors have the patience and understanding to see long-term projects through to their completion, including the research and financing required by them. The different long-term projects create critical know-how to the region which in turn helps the region to develop and attracts international actors to set up in the region”, Hellén says.

Foam forming and the novel solutions it offers have also been made available to the various SMEs, according to Hellén. These smaller-scale companies can benefit significantly from the technique, as they can test their product concepts and conduct different kinds of pilot-runs with the help of VTT without investing massively in the required infrastructure. One of the future areas of research, Hellén mentions is the replacement of oil-based and non-biodegradable polystyrene with a more environment-friendly and resource efficient material.

“Due to the significant interest, VTT is in the process of investing in another pilot-scale machine that would allow us to produce even more porous material. In the framework of the next project, this opens up new applications for the non-woven fabric, among other things. The continuum that exists between the projects is vital so that we can utilize the existing knowledge and data in new arenas and in answering new problems that arise”, Hellén stresses.